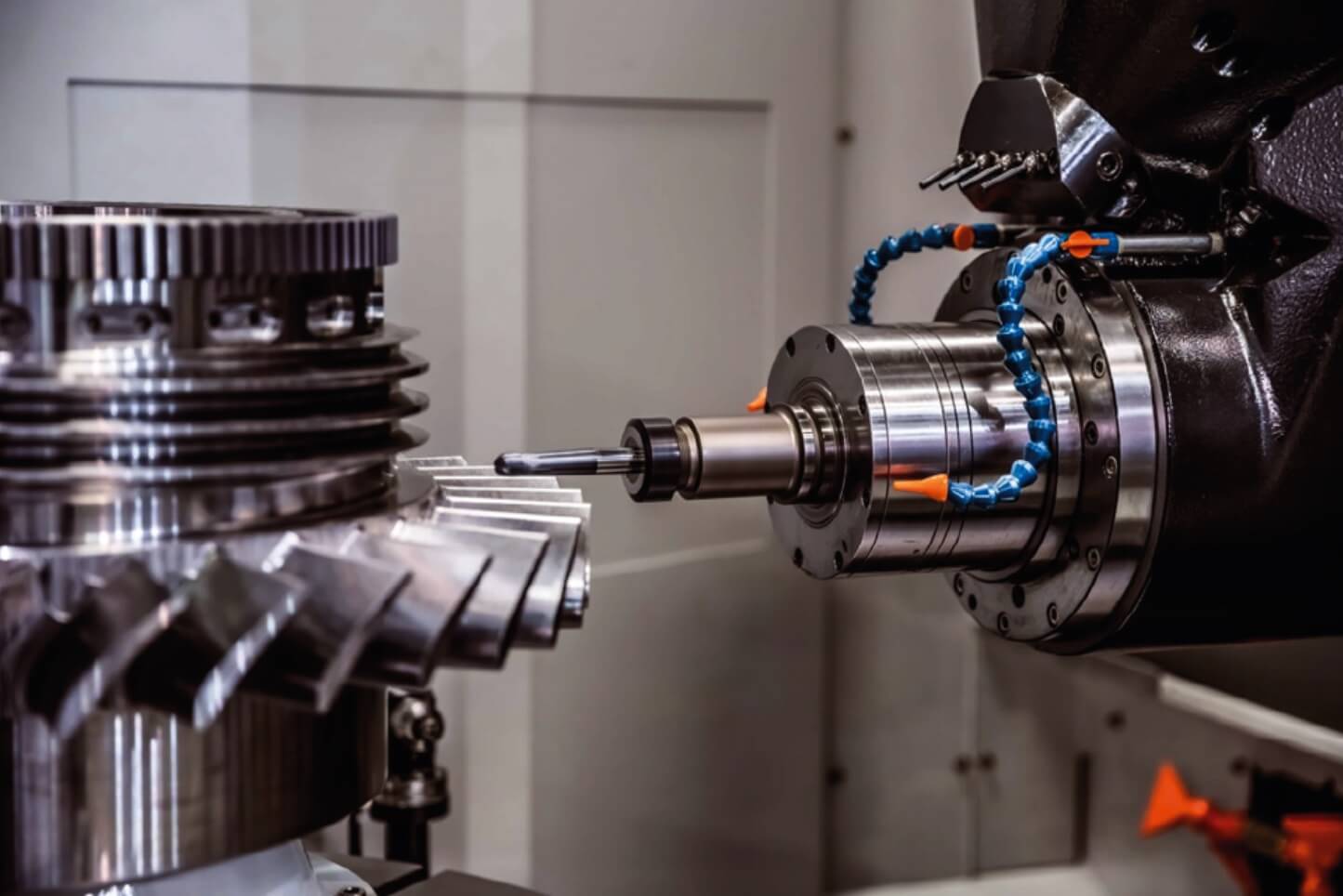

CNC Milling.

Milling solutions

Our machines have a capacity of up to 1metre long x 0.5m wide x 0.5m high And our tooling magazines can hold up to 60 tools. Our maximum spindle speed is 15,000 RPM

We have a mixture of 3 axis, 4 axis and dividing heads enabling us to produce even the most demanding and complicated parts

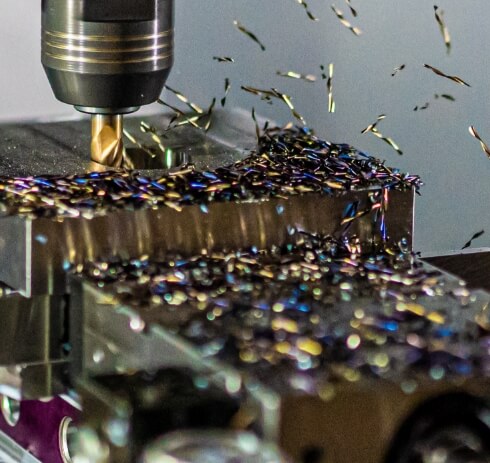

Milling Capabilities

vertical milling

We have a number of 3 axis vertical milling machines with spindle speeds up to 12,000 rpm, 30 tool turrets and bed sizes up to 1000mm long x 500mm wide

Horizontal milling

for those complex, time consuming parts we have a Matsuura 4 axis horizontal machining centre with 60 tool capacity, 15,000rpm spindle speeds. For even greater efficiency we have a 5 pallet auto loader so we can run larger batches continuously and efficiently

4th axis milling

We have both 4th axis trunnions and dividing heads, enabling 3D milling of complex shapes without the need for constant repositioning of work giving greater efficiency

Multiple work holding options

Toi ensure we are always able to hold a workpiece in the most efficient manner we have multiple too holding options available, from Kurt vices to a full suite of Micro lock vices.

Our milling plant list is as follows:

- Doosan DMN400 3 axis vertical CNC mill

- Doosan DNM500 3 axis vertical CNC Mill with Nikken 4th axis trunnion

- Doosan DNM500 3 axis vertical CNC Mill with Nikken 4th axis trunnion

- HAAS VM2 3 axis vertical CNC Mill with HAAS 4th axis dividing head

- HAAS VM2 3 axis vertical CNC Mill with HAAS 4th axis dividing head

- Matsuura ES450 4 axis horizontal CNC Mill with 5 pallet auto changer

We also have manual milling capability with 2 manual 3 axis mills and a number of pillar drills