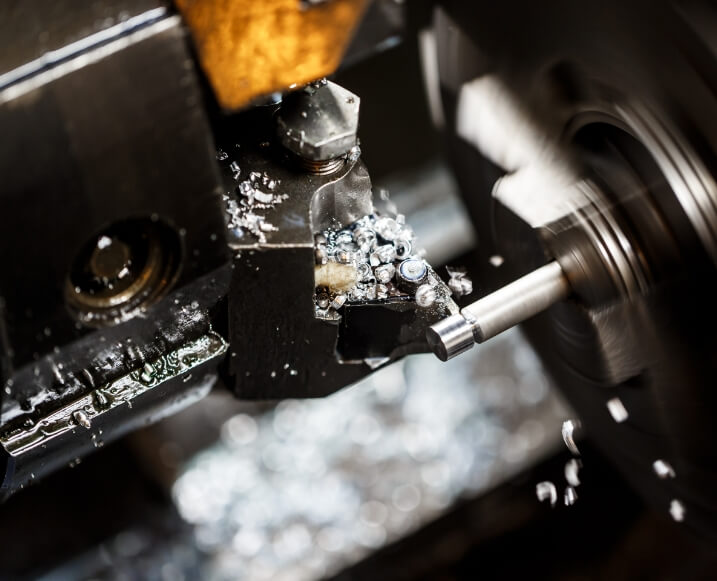

CNC Turning

Turning solutions for almost all requirements

The current portfolio of machines includes 3 axis lathes, with chuck capacity of up to Ø200mm and 500mm length. Our experience with these machines enables us to program complex milled profiles on turned parts, maintaining high accuracy on key features.

Most of our lathes also feature sub spindles enabling us to undertake complex components with multiple operations and produce finished components without the need for intermediate setting.

3 axis turning

3 axis turning means we are able to turn even the most complicated profiles to meet our customer specifications

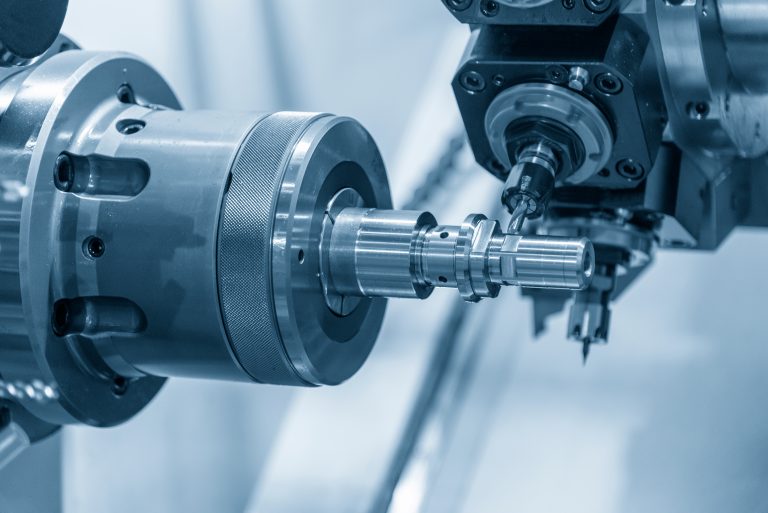

driven tooling

Having multiple driven tooling stations on every machine means we can perform numerous operations on a component without ever taking the part out of the machine.

sub spindles

The majority of our lathes feature sub spindles, allowing us to perform multiple operations on a part without having to perform multiple setting operation, giving us a more efficient and faster production for complicated components.

Bar Feed

Bar feeding means for work in larger batches we can automatically feed our machines with bar

Our Turning plant list is as follows:

Doosan PUMA 2000SY CNC turning centre with y axis and sub spindle

Doosan PUMA 2000SY CNC turning centre with y axis and sub spindle

Doosan PUMA 2000SY CNC turning centre with y axis and sub spindle

Doosan PUMA 2100SY CNC turning centre with y axis and sub spindle

Doosan LYNX 220LY CNC turning centre with y axis

Doosan LYNX 220LY CNC turning centre with y axis

We also have a number of Hardinge manual lathes for finishing operations